E-beam Deposition

Silson offers an e-beam deposition service that transforms the mundane into the extraordinary. With our extensive range of coating thicknesses, ranging from 1nm to a robust 200nm being typical, we are more than willing to cater to your specific requirements.

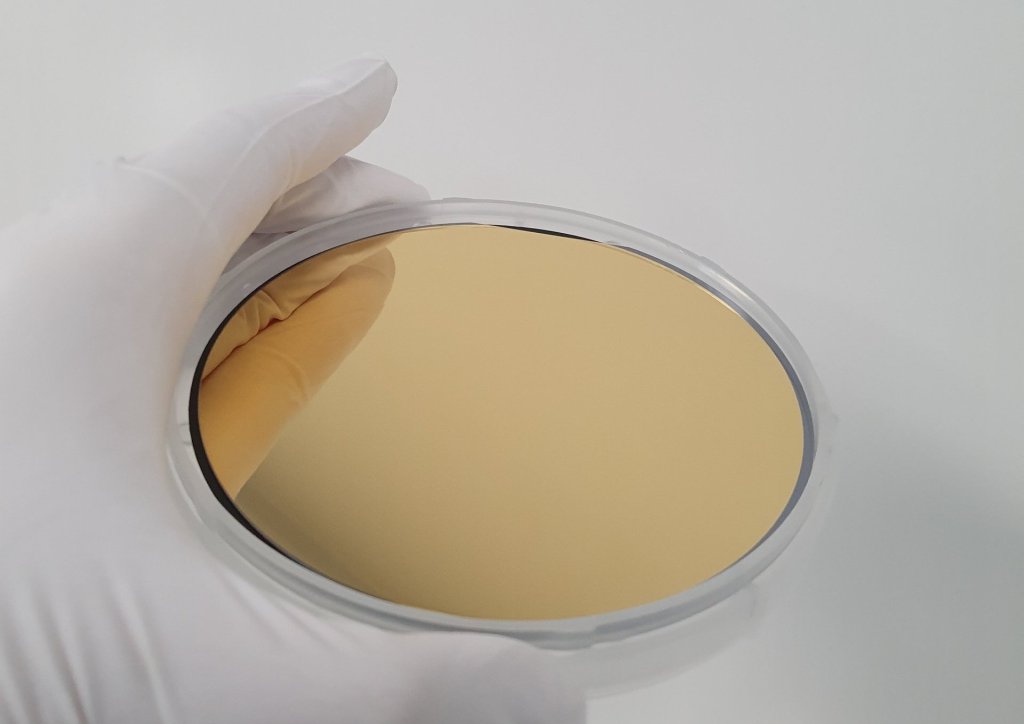

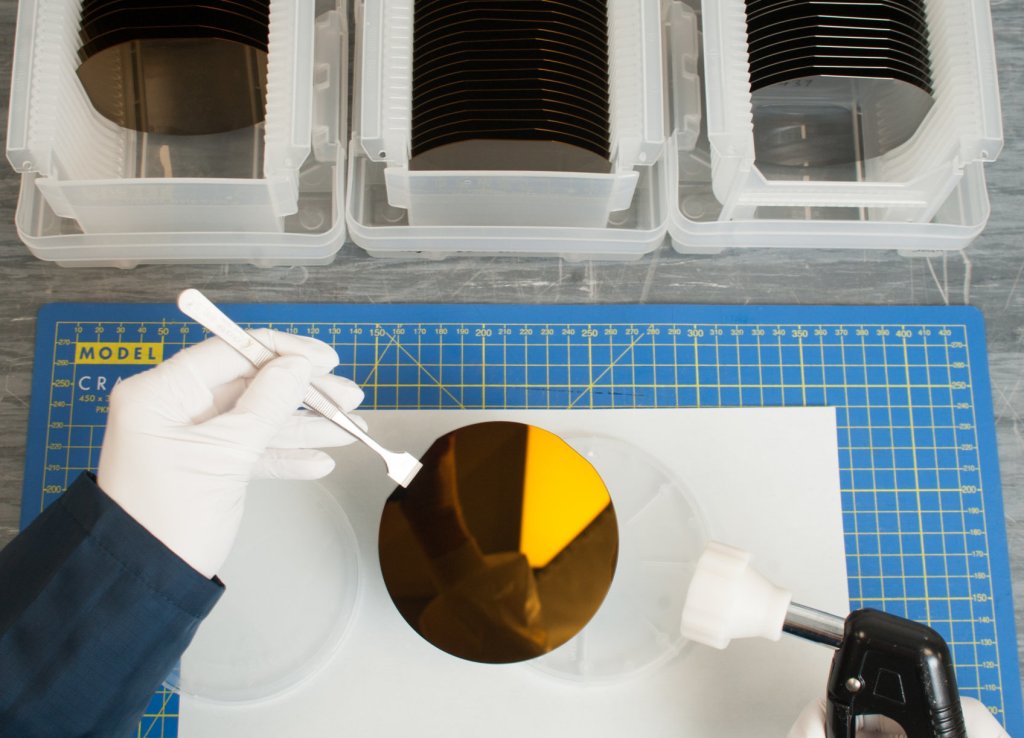

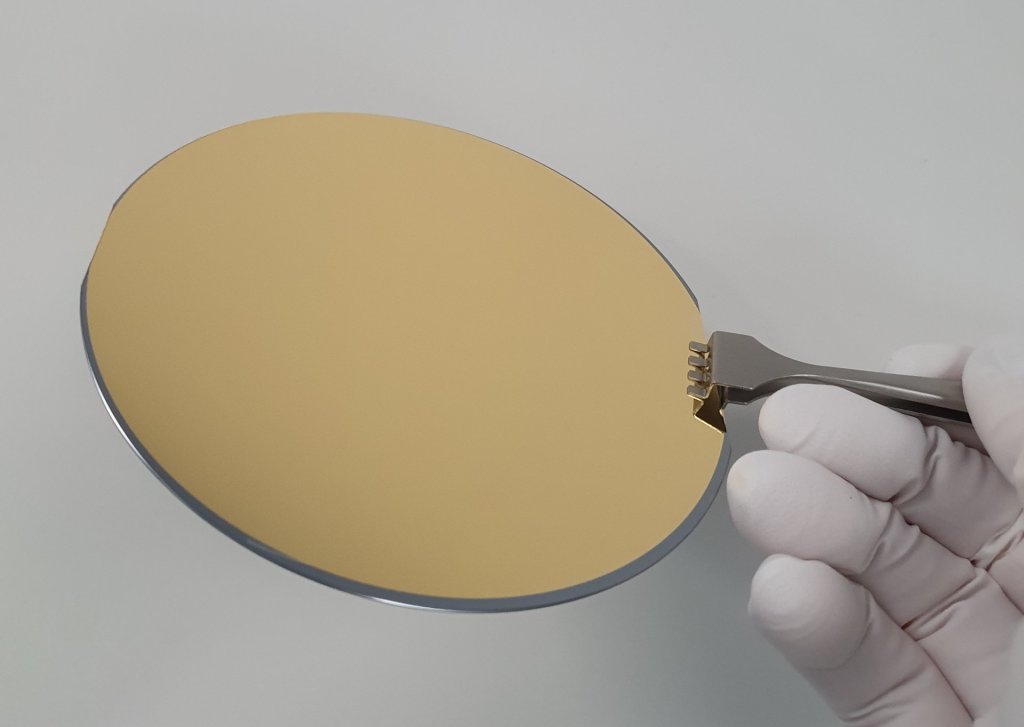

Silson takes pride in its ability to accommodate both 4-inch and 6-inch wafers, ensuring that your projects are not constrained by size limitations. We can also coat customer supplied wafers or substrates.

At Silson, we understand that one size does not fit all. Our pricing model is tailored to a “per run” basis, and costs vary depending on the chosen material; please contact us with details of your requirements regarding coating material and thickness.

Electron Beam Evaporation, also known as e-beam evaporation, is an exceptionally powerful technique for physical vapor deposition. It enables the evaporation of materials that are challenging or even impossible to achieve through standard resistive thermal methods, especially high-temperature metals and materials such as silicon oxide and other optical films.

The concept:

E-beam deposition utilizes a magnet to focus electrons into a beam directed towards a crucible containing the desired material for evaporation. The energy transferred initiates the evaporation process. Most metals, such as Aluminium, initially melt before evaporating, while ceramics sublimate. The resulting material vapours exit the crucible, coating the substrate.

At Silson, we offer a diverse range of materials for deposition, including titanium (Ti), gold (Au), platinum (Pt), silver (Ag), chrome (Cr), copper (Cu), and nickel (Ni). Our offerings go beyond mere functionality; these coatings can be plain, serving filtration and charge dissipation needs, or intricately patterned into electrodes, heaters, and various functional devices, accommodating different scales of 4-inch or 6-inch wafer sizes.

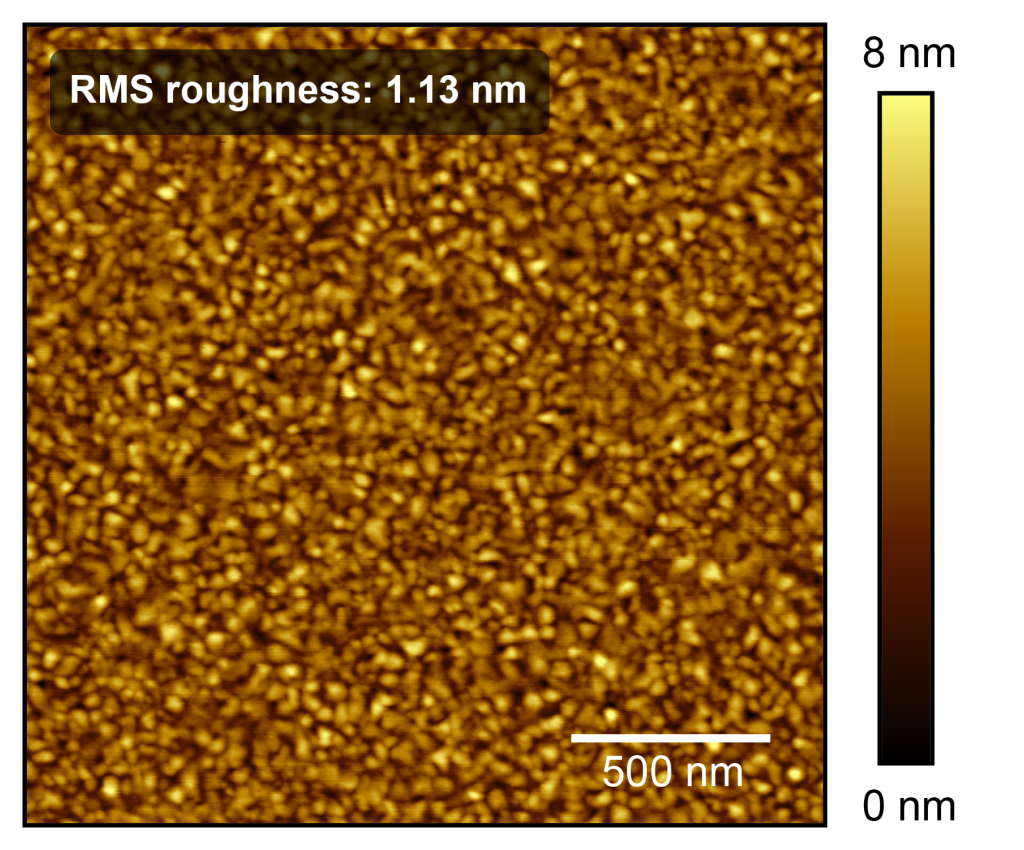

Thank you to NuNano for this AFM image of one of our wafers coated with 50nm Au on 5nm Ti, with an RMS roughness measurement.