Differential Pressure Windows

While most membranes supplied by Silson are used as simple sample supports for x-ray or electron beam imaging, in some applications they are used as vacuum windows or differential pressure windows, with a different pressure on either side of the membrane.

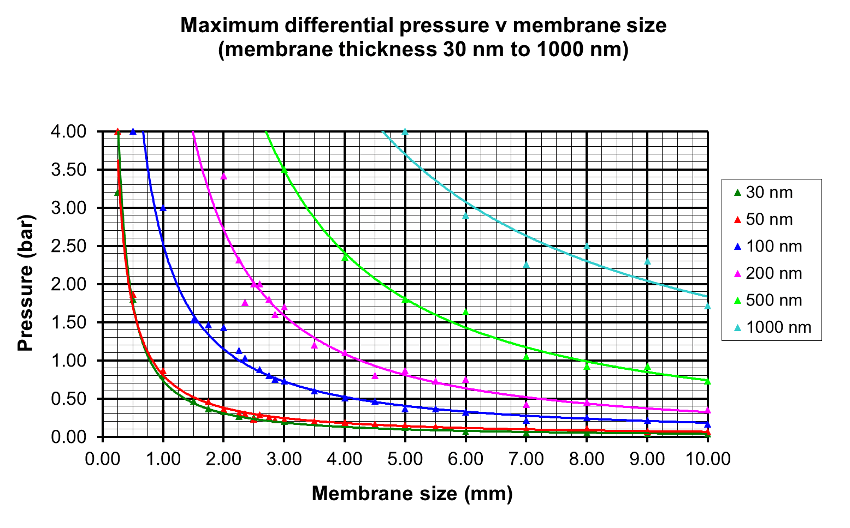

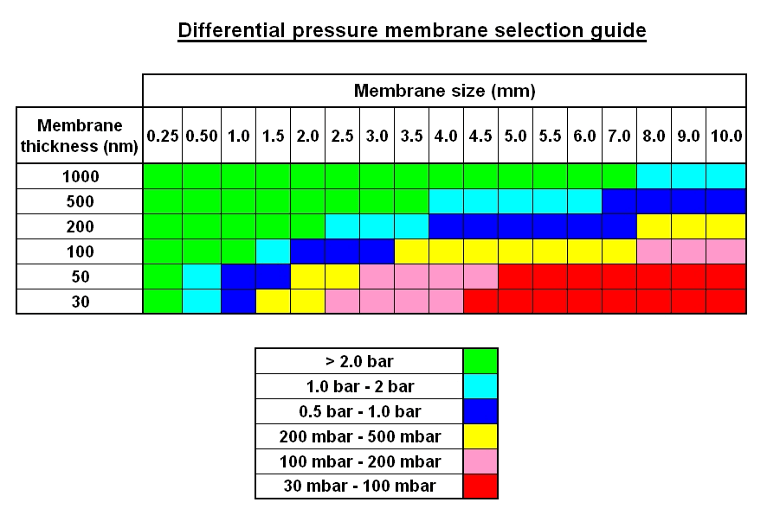

The pressure that a membrane will withstand varies greatly with material and membrane size and thickness. Silson has undertaken an extensive characterisation of these parameters in order to provide the best guidance to customers selecting membranes for specific differential pressure requirements. Membranes are tested by over-pressurising with gas to a maximum burst pressure of 4 bar. For membranes that burst below this level the failure point is recorded and an average calculated.

Please see the data below for our silicon nitride membranes:

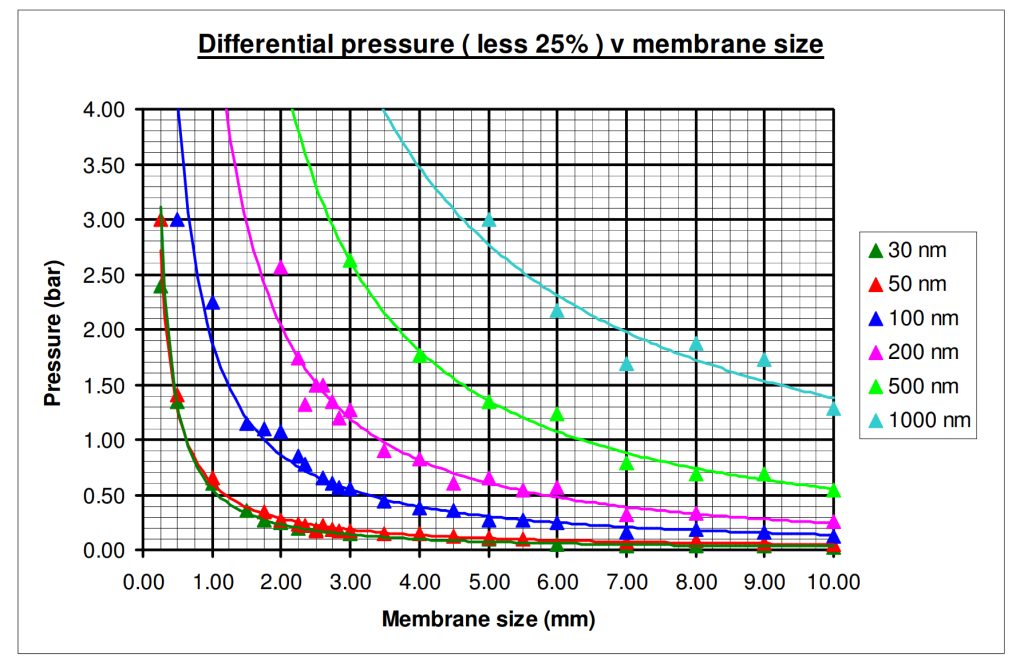

The following graph includes a 25% “safety factor”:

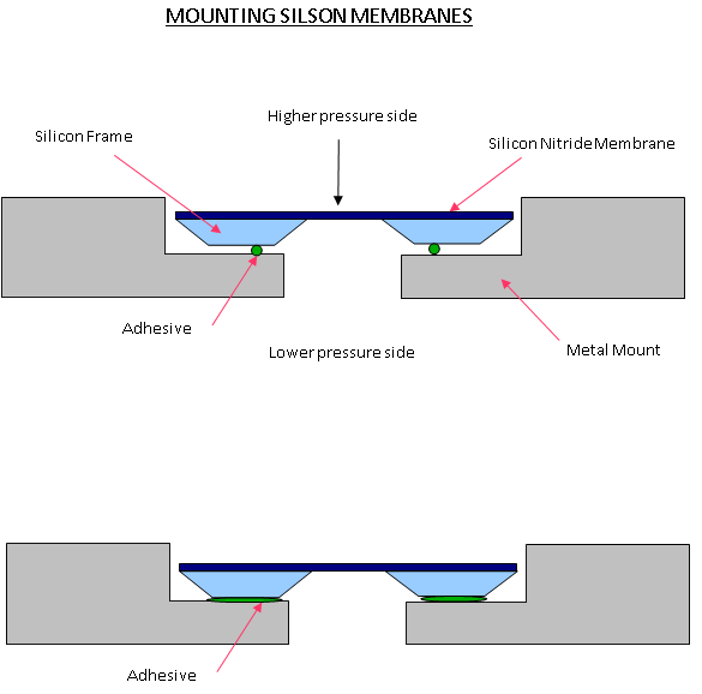

The pressure that a given membrane will withstand is highly dependent on direction and it is important that the force is applied from the flat membrane side, pushing the membrane against the substrate as shown in the diagram. Significant back pressure can cause the membranes to delaminate from the substrate.

Membranes can be supplied individually for mounting by the customer or pre-mounted in Silson standard mounts or custom mounts to customer specific requirements.