Perforated Membranes (Membranes with Holes)

Silson inspects 100% of the membranes it supplies under high magnification differential interference contrast, Nomarski, microscopy which allows the detection of any particles or holes. A defect-free membrane should be helium tight and for certain applications able to withstand a differential pressure depending on the size and thickness of the membrane.

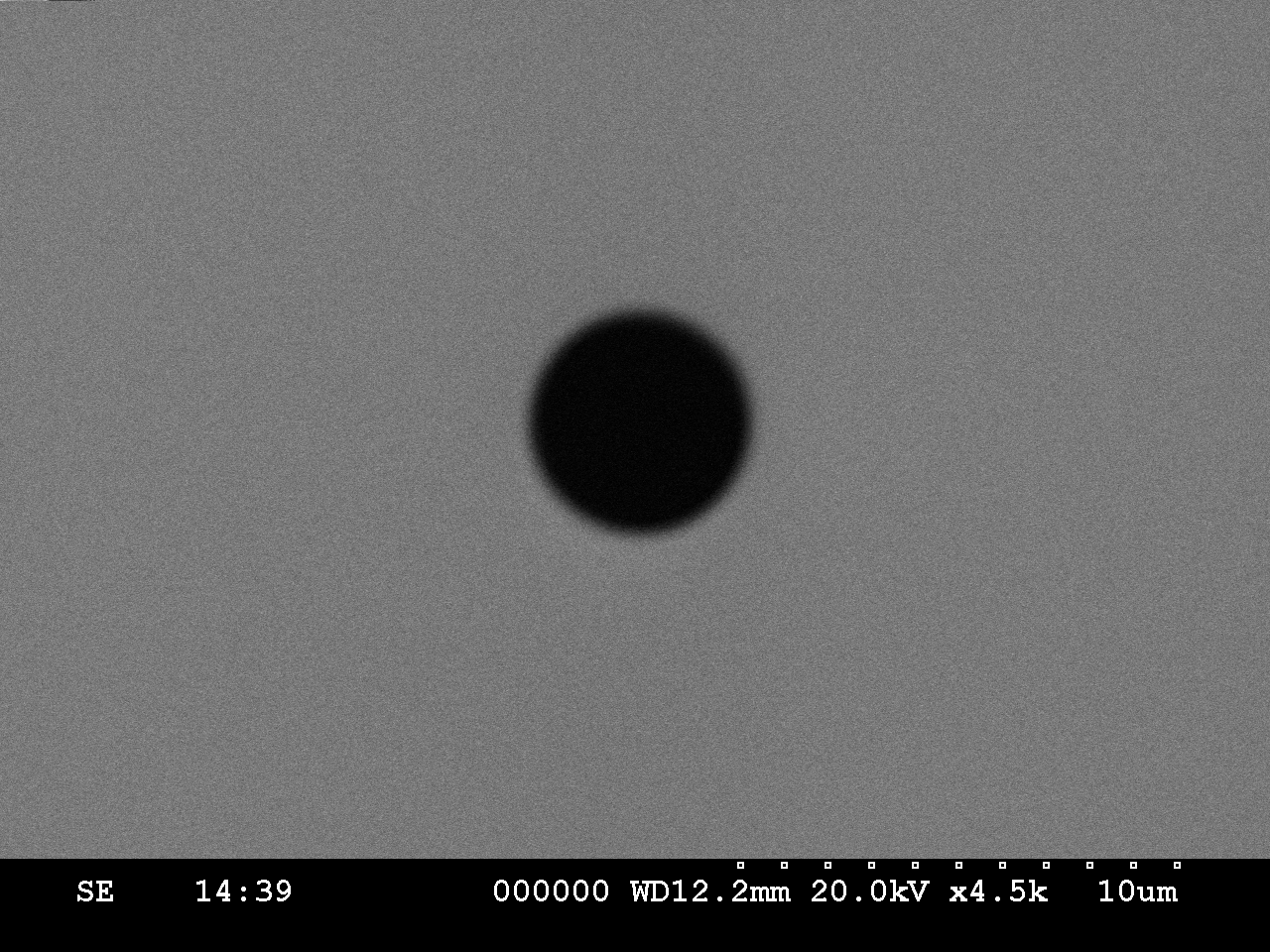

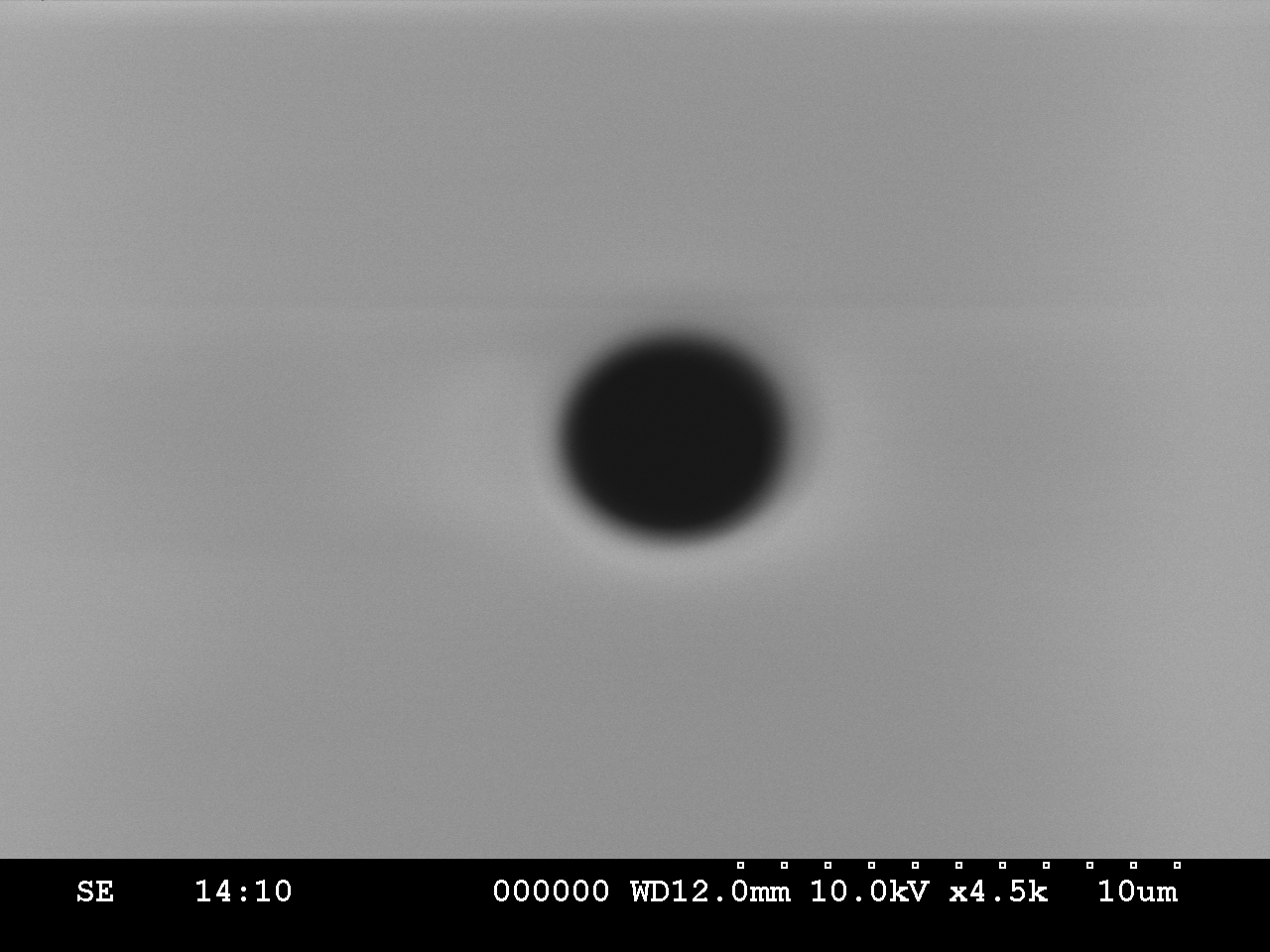

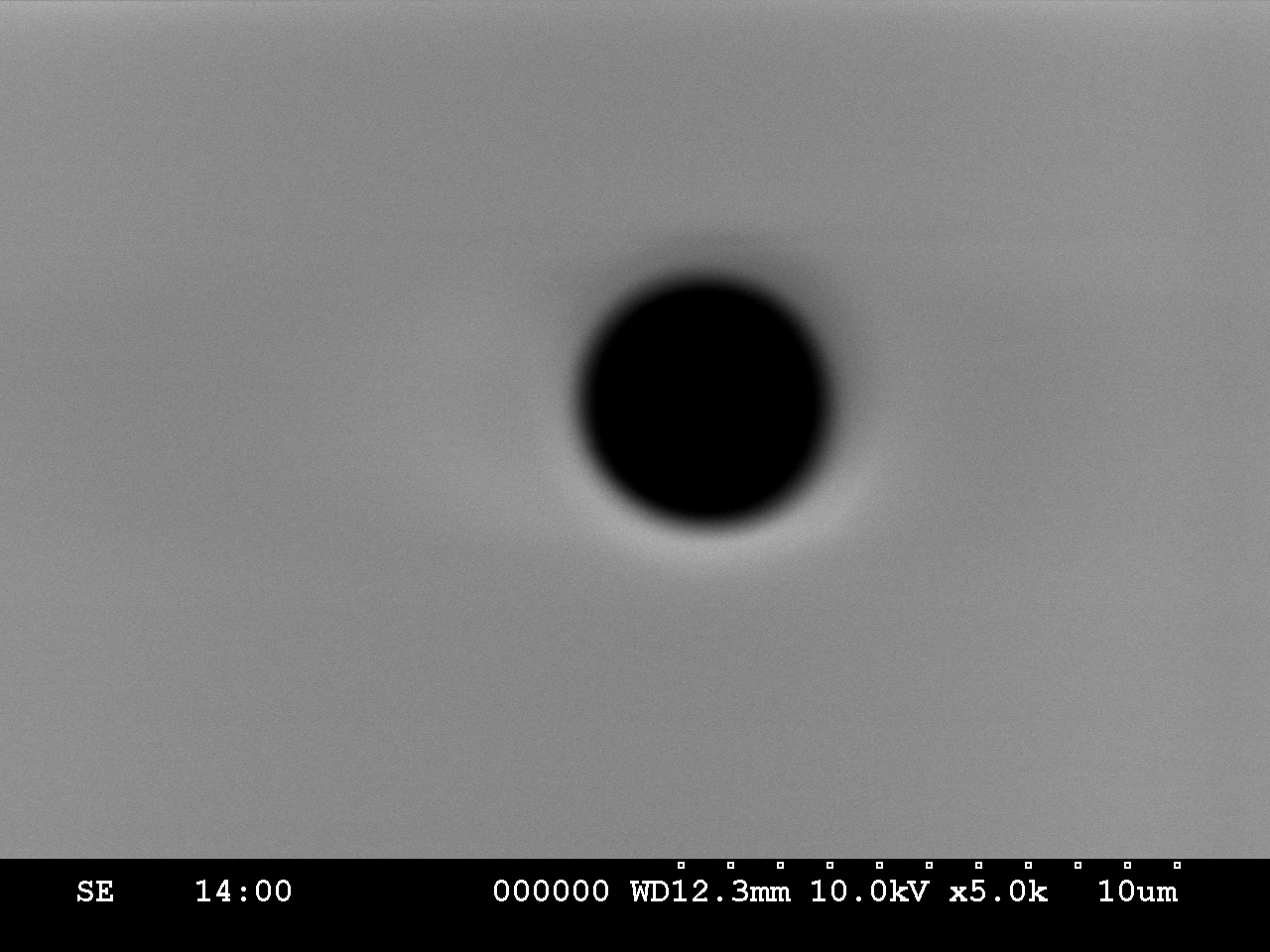

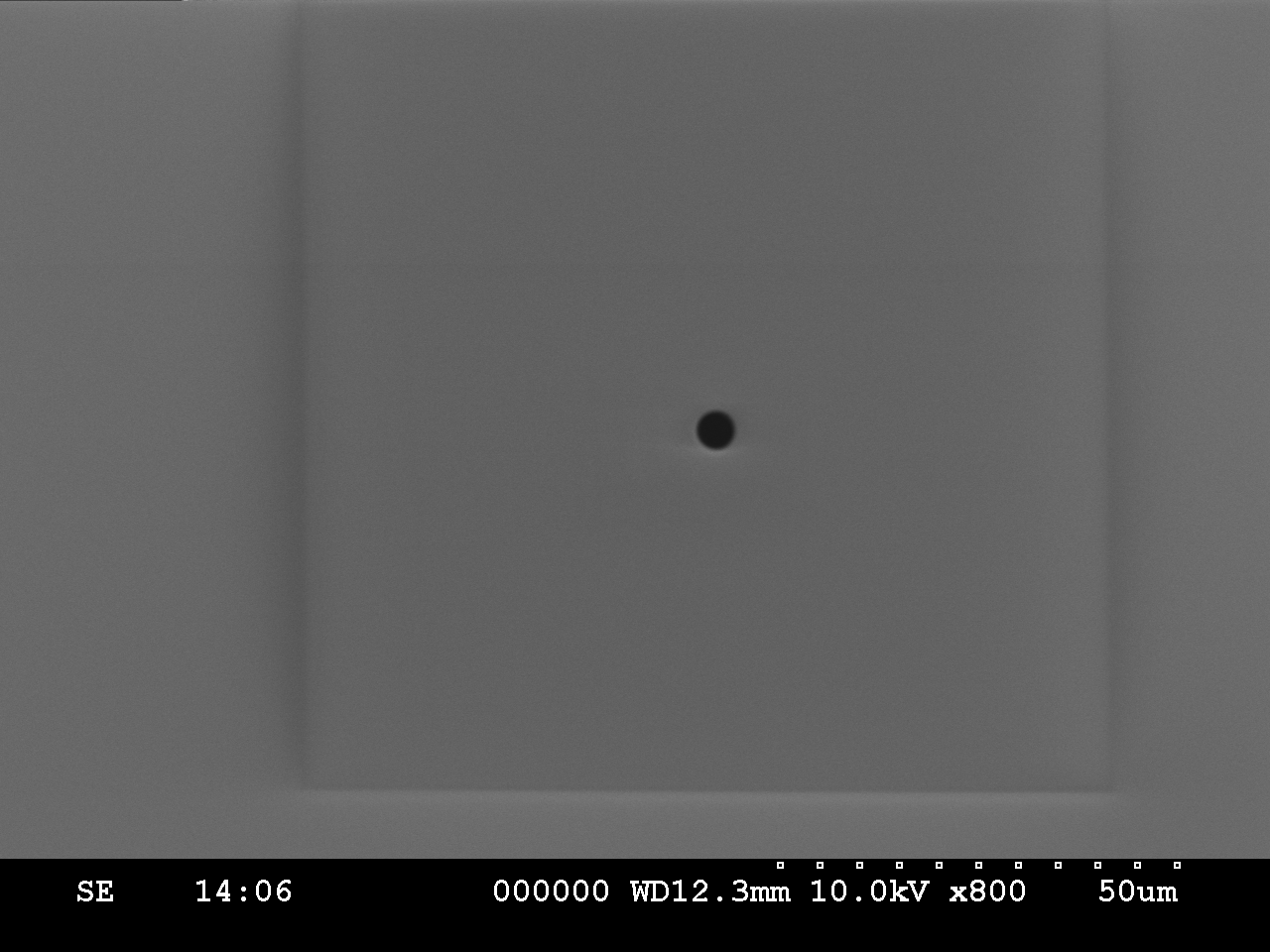

For certain applications however, it is desirable to have one or more holes or pores created in the membrane and a wide range of products are now available. The most popular designs consist of a 5.0 mm x 5.0 mm frame, 200 µm thick containing a 0.1 mm x 0.1 mm, 200 or 500 nm thick with a single pore in the centre. The hole diameter varies from 1.0 µm to 10.0 µm in 1.0 µm intervals. 12.0, 16.0, 18.0, 20.0 µm and a range of larger pores are also available from stock. Alternative designs can also be manufactured subject to minimum order quantities. Here are some pictures taken on our SEM (scanning electron microscope) of our single holes:

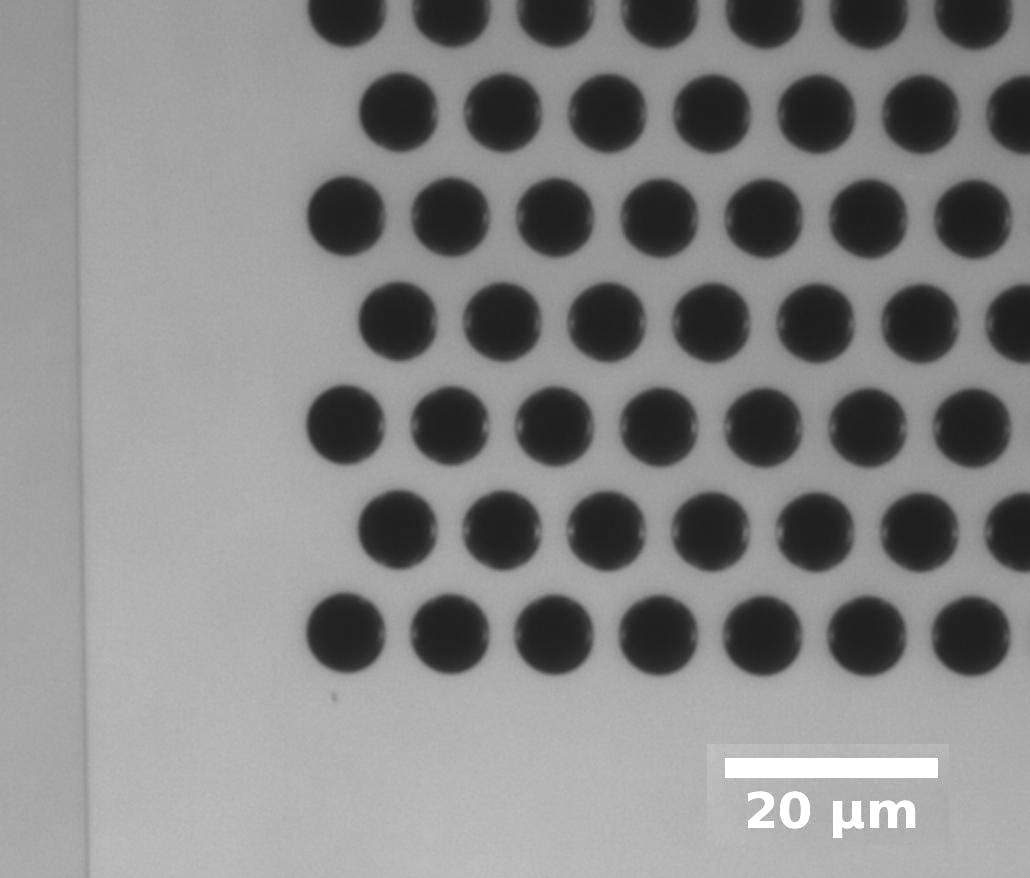

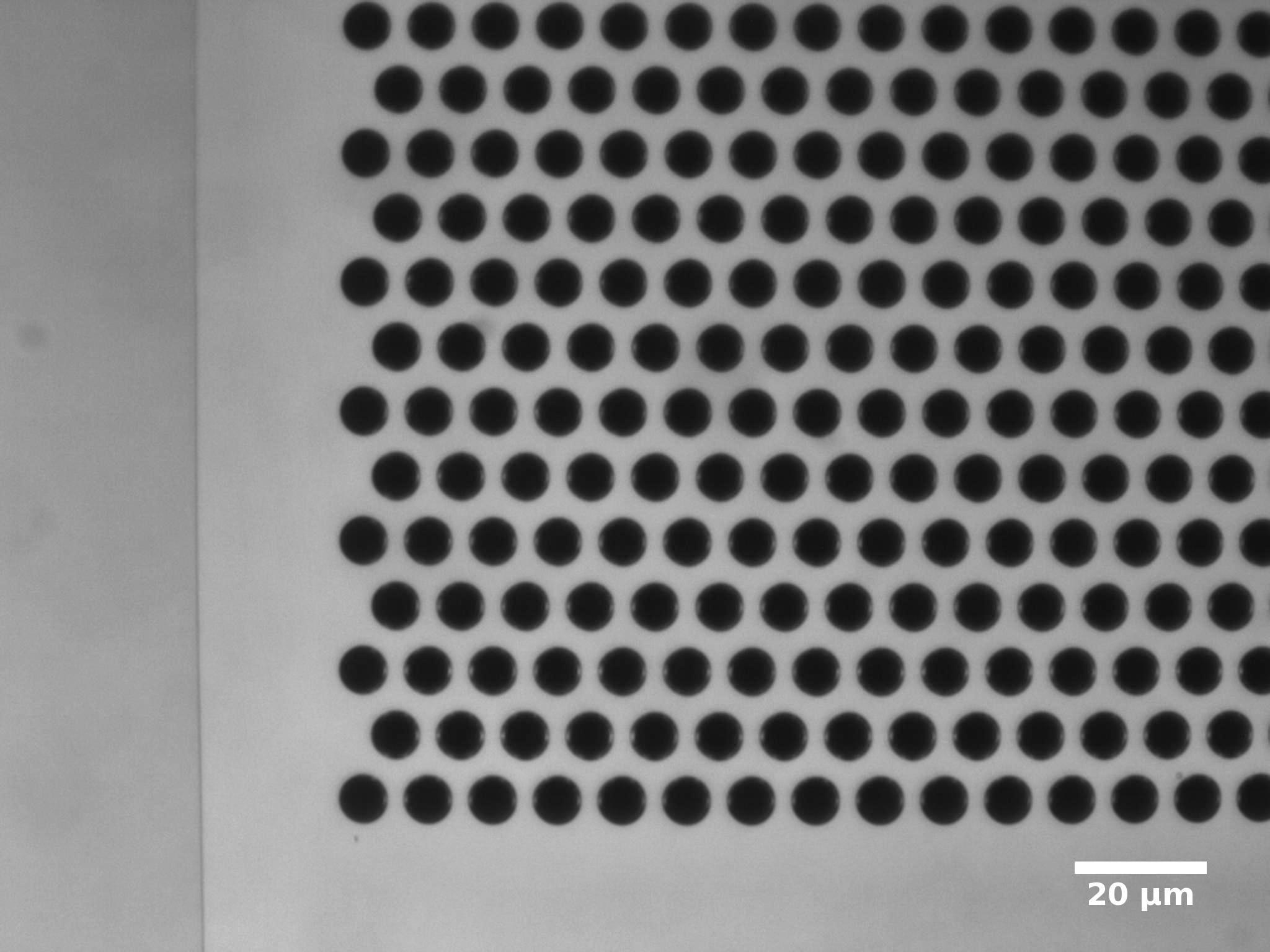

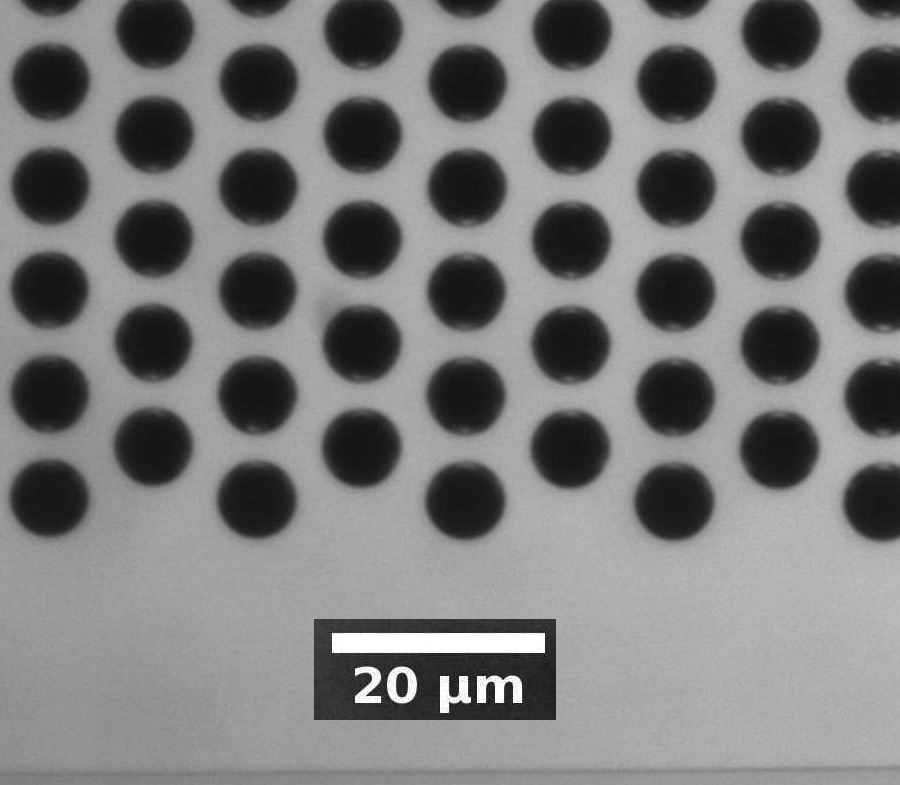

Arrays of holes are also possible and are particularly popular for TEM applications; we now manufacture our arrays of holes with a hexagonal design:

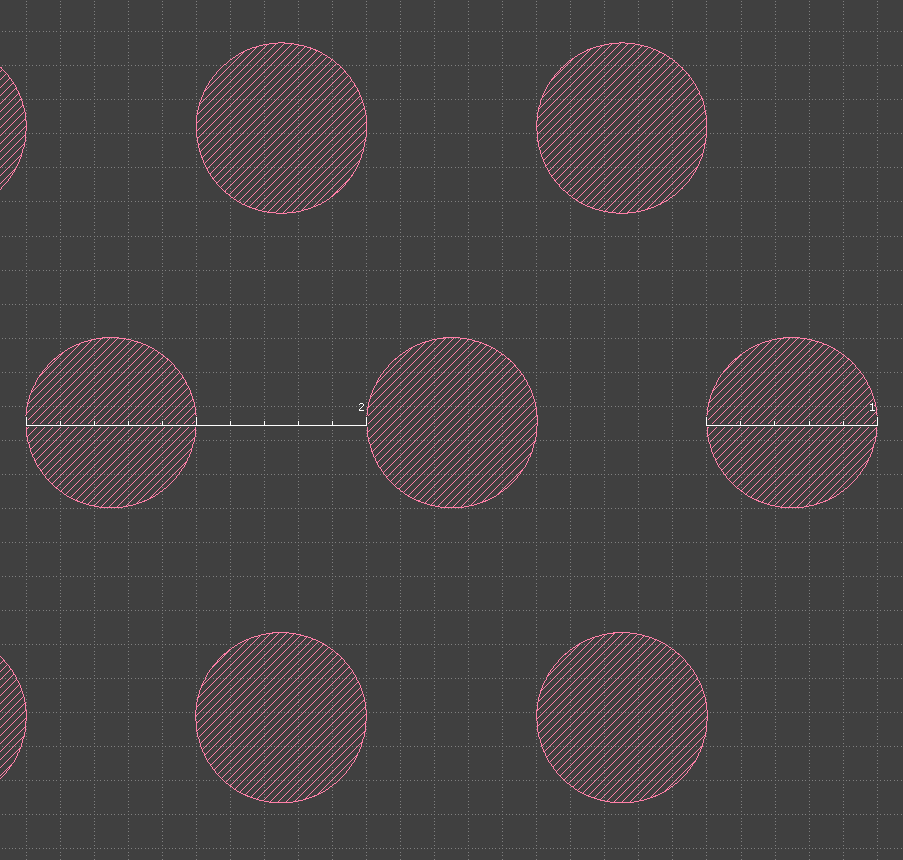

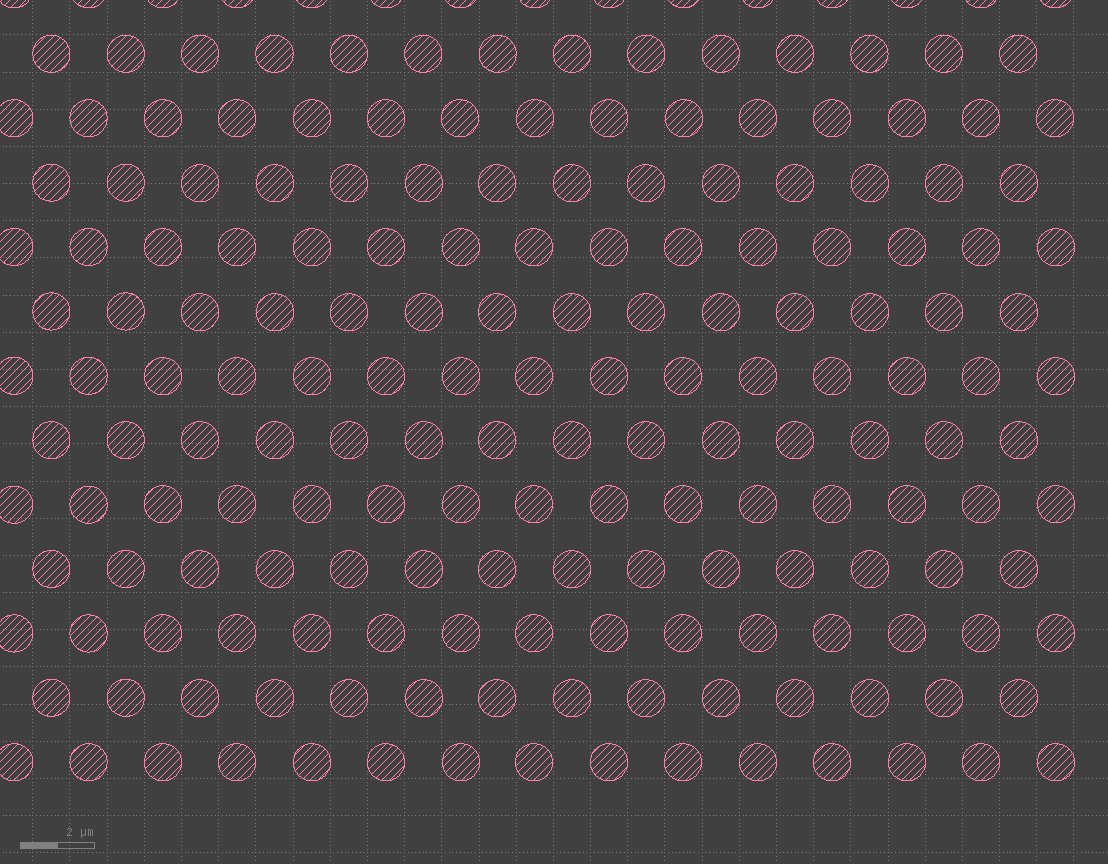

These are some drawings of one of our designs which consists of 1 µm holes on a 2 µm pitch in a hexagonal array:

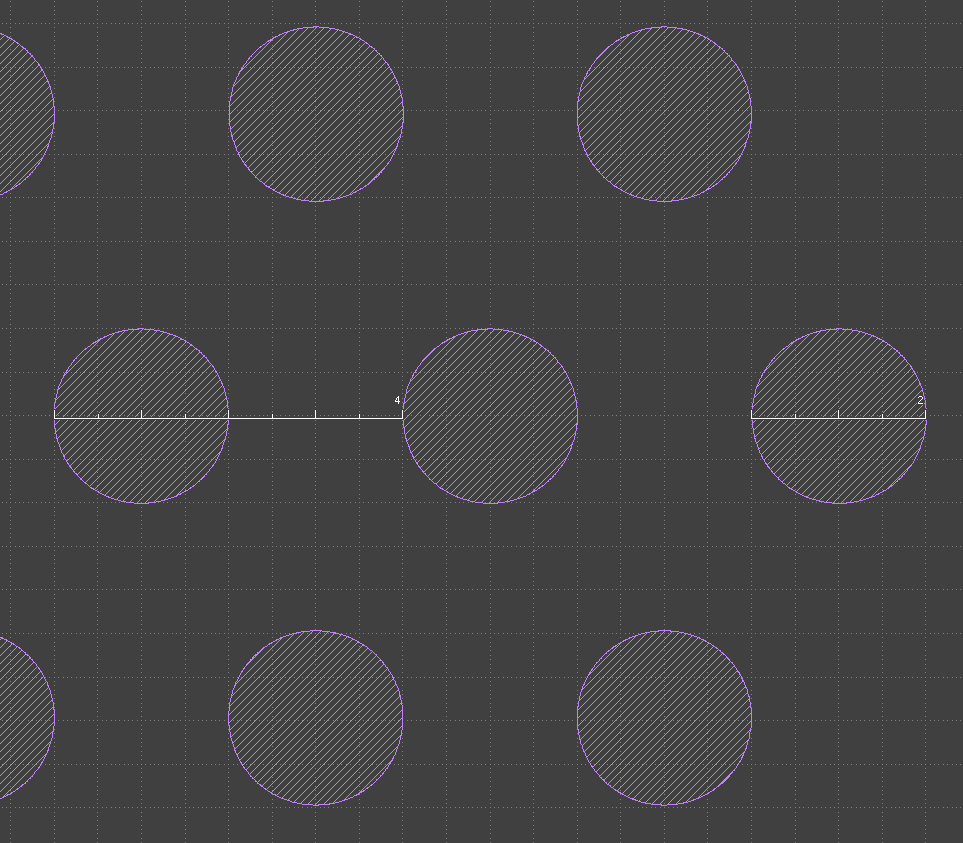

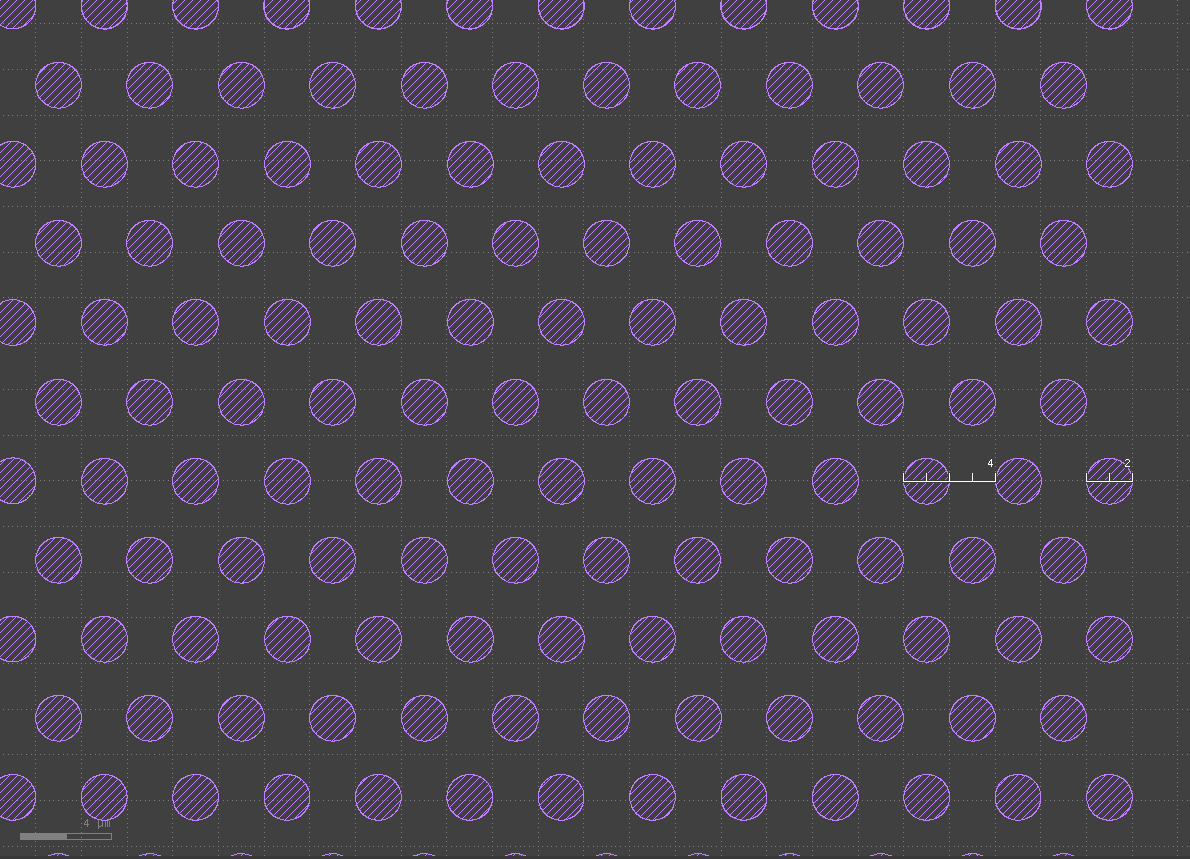

And this design is of different dimensions, consisting of 2 µm holes on a 4 µm pitch in a hexagonal array:

Perforated membranes may also be covered with graphene to give the thinnest possible sample support or for the inspection of the graphene itself.